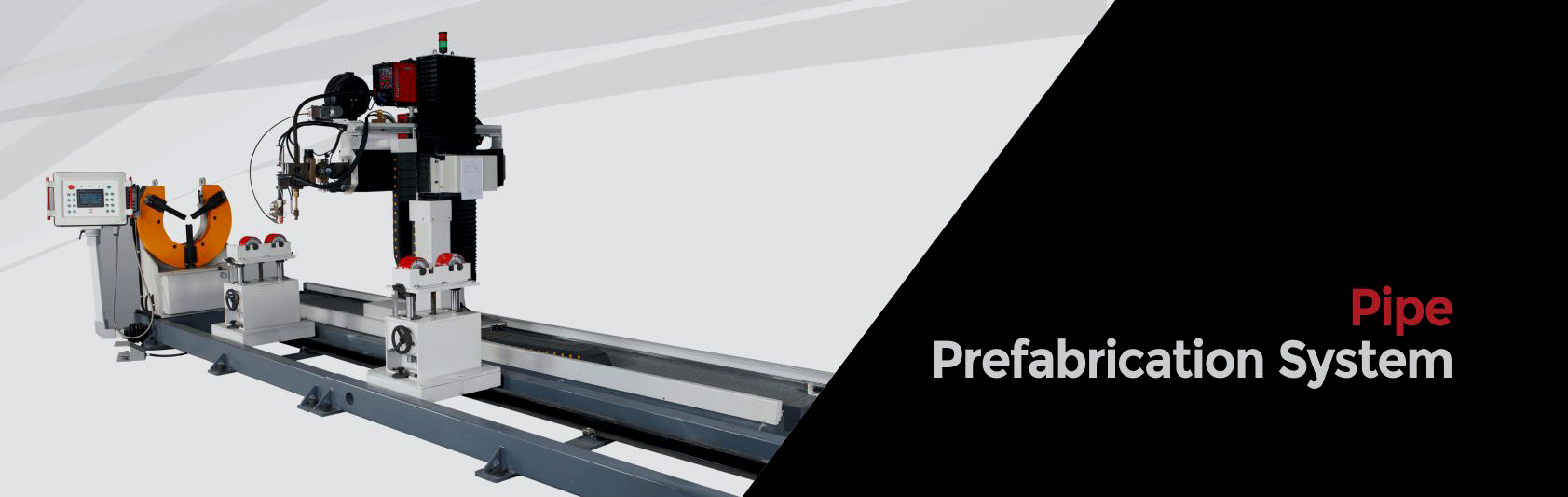

HL Longitudinal Seam Welding System

The system suits slip-on flange four-fillet-seam welding simultaneously, pipe to flange, taper pipe to flange. The system can be used in shipbuilding, maritime work, engineering machinery and other industries.

Brief

According to requirement of customer, the system uses pulse MAG welding procedure to deal with root pass, filling pass and cap pass, which realize no spatter welding for reducing line heat input in welding. Through expert parameters in power source, it can realize uniform forming and handsome welding joint under any welding current.

Features

- Advanced profiling tracking device which ensures constant distance between torch and pipe

- Integrated fit-up, tack welding, conveyor system and welding system together to inprove efficiency

- Automatic pipe load/unload

- Suitable for OD 2”-8” pipe to flange welding

- Specially designed for slip-on flange four-seam welding simultaneously

- Suitable for shipbuilding and construction machinery.

Specification

- Material: carbon steel and standard angle welding joints of some types of stainless steel

- Welding procedure: Pulse MAG

- PIpe size: OD Φ80~630mm, length 100~500mm wall thickness δ4~12mm

- Structural systel: pipe plug-in flange;

- Joints quanlity: profile test.